We take pride in every candle we make and nothing is more critical than the pouring process. Today we are getting a behind-the-scenes tour from Erin, our CPO, Chief Pour Officer. She is walking us through the operation of the best way to pour a candle.

Step 1: Ensure that all of your pouring utensils are clean: Here at Poured Goods, we make ALOT of candles, so, it is incredibly important that our instruments are properly cleaned. That way you get the purest scent with every candle you buy! This includes the melting vessel, the scent pourer, and your candle jar.

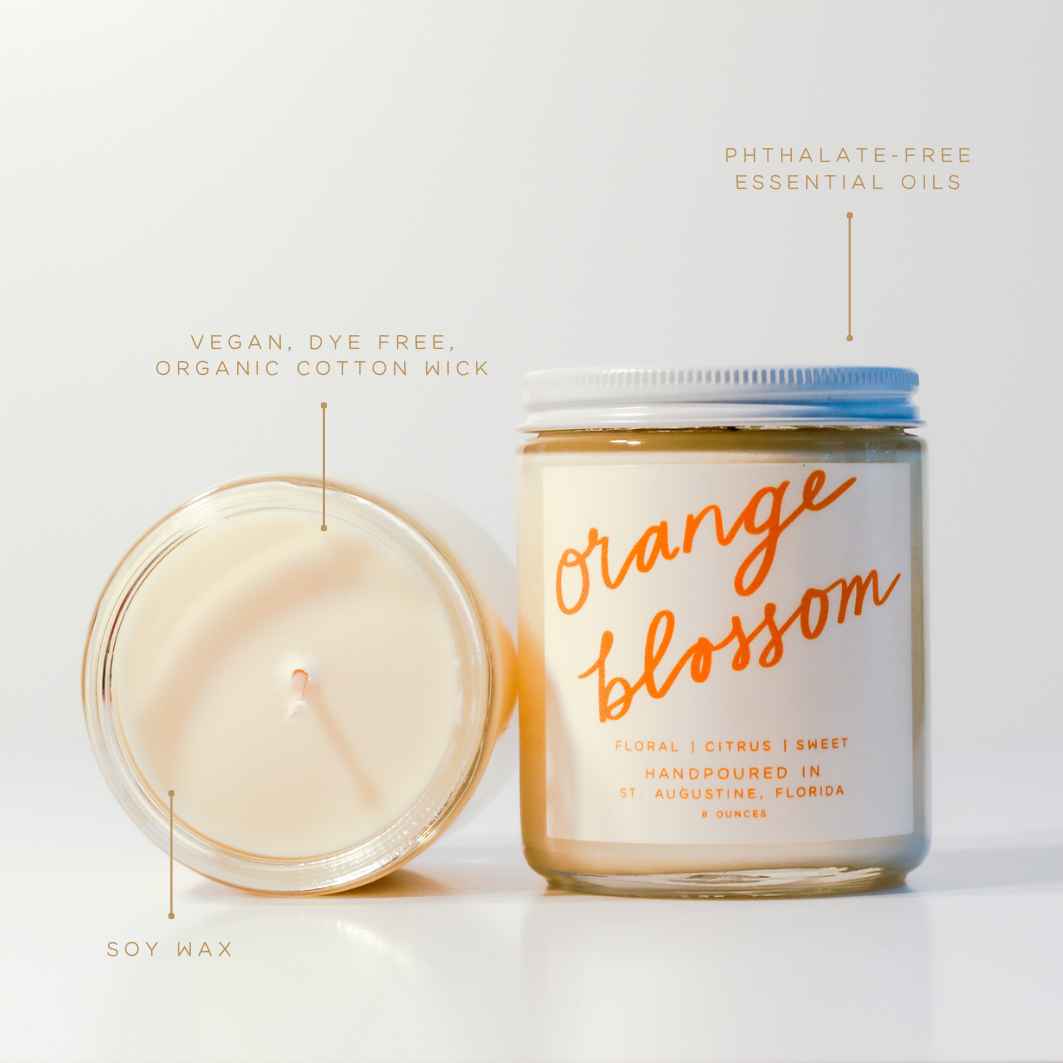

Step 2: Prepare the wax: There are many kinds of wax to choose from when making candles, however, in our opinion soy wax is the way to go. All of our candles are pure soy wax. To pour the perfect candle we want our wax to be completely melted at 170 degrees Fahrenheit. This way when we mix our fragrance into the wax it will integrate properly.

Step 3: Choose and mix in the fragrance: Choosing a fragrance can be one of the hardest parts of the candle-making process! Do you go floral, earthy, or fresh? If you decide to go with a maker like Poured Goods, we walk you through this process. With various fragrance profiles to choose from, it can be easy to become overwhelmed. Our carefully curated fragrance library gives you an in-depth understanding of scent profiles on the notes, and essential oils found in our scent blends. Once you've chosen the scent we mix this directly into our hot wax, stirring continuously for 3-5 minutes.

Step 4: Prep the candle: We securely attach the wick to the bottom of the jar so that it does not float away when the wax is poured. We like to use wick tabs. This works as a sticker that you attach to the bottom of the wick and then sticks directly to the bottom of the jar. When we first pour the wax the wick is not straight up and down but we address that once the jars are full.

Step 5: Pour the wax and let the candle rest: It takes approximately 24 hours for the candles to fully cure. We use wick holders or standard wooden clothespins to keep the wick upright during the cooling process. Once the wax is poured we stand the wick upright and attach the clothespin at the height of the jar. We let the clothespin rest on the rim of the jar until the candle is fully set.

Step 6: Clean, label, pack, and ship:

Now that the candles are ready, we label, pack and ship them to you! Candles are what we do and we have perfected this process to ensure every candle you receive is perfect for your customers. If you are new to selling candles and want to learn about what's next, reach out, we would love to talk!